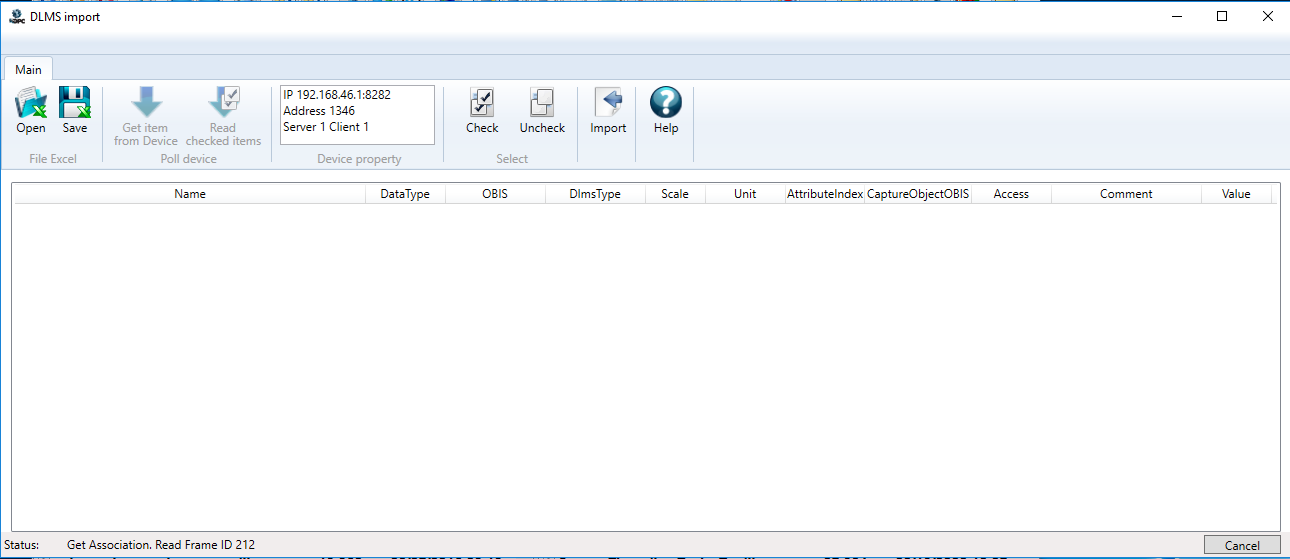

Apart from import from Excel you can also obtain the complete list of the variables from the device. To launch it, you need to press the Get item from device button. This will start the meter polling according to the settings made on the OPC server. The operation status is displayed at the bottom of the window.

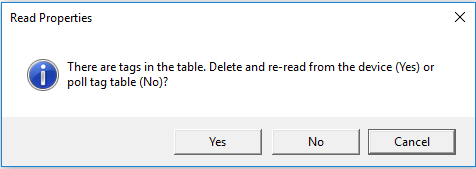

At the same time, if the table already contains any tags (for example, loaded from Excel), when you start receiving tags from the device, a window appears with an offer to clear the table and read all the parameters from the device or read data from the table ("over").

In the second case, the utility reads the parameters and then apply them to the existing table (data type, measurement units and scale). This scenario can be applied in case, if you already have a generated table with the required variables, but the meter was changed for a different modulo and you need to adjust the scale and data type (each manufacturer defines the data type and scale in DLMS device at his discretion). If some of the tags are unavailable in the device, they are locked in the tree.

Note. Normally, the devices have many tags, therefore the complete reading of these tags may take some time - several minutes. The progress is displayed at the bottom of the window.

When the reading is over check the required tags and press the Import button.

You can also save the tags to Excel file using the Save button in menu. However, if some of the tags are checked in the tree, a window offering to save all the tags or only the selected ones appears. Thus, you can check the tags you need in the project and save them in Excel file for the later use. You can also save the variables in Excel, adjust them (add or change the hierarchy, translate comments, change variable names), and then import the updated file using the Import from Excel mechanism.

Import utility operation algorithm

The following operation algorithm is used during the poll and table generation:

1.The special Association object is read (each meter must support it). The list of objects represents a structure that contains logical name, access type, class identifier (object).

2.The objects of supported type are selected from the resulting collection of objects.

3.The poll of each object properties - its scale (Scaler) and measurement units (Unit). Scaler is necessary for correct value output (the manufacturer can represent a real number as an integer with a point offset).

4.Reading of the tag data types.

5.All the objects related to Profile Generic are read of their capture objects (Capture Objects), then each of these objects are searched in the list of the other variables and the parameters of these variables (scale and measurement unit) are then used in the profile tag.

After reading and setting up the tag collection the table is generated. Each object of Data and Register type create one tag - measured value. Extended Register object creates a group with two tags - Value and Time. Demand Register creates a group with 7 tags - CurrentAverageValue, LastAverageValue, Status, CaptureTime, StartTimeCurrent, Period, NumberOfPeriod. Profile Generic object creates a group with a number of tags equal to the number of minute capture objects (one tag - one capture object), time tag (the time is not added to the structure, since it serves the basis for HDA timestamp. However, if the profile has no time object, this profile is considered as unsupported and is not added to the table).

When the list of tags is ready, their names and comments are added. Since the major part of variable identifiers (OBIS) are rigidly assigned to certain parameters by DLMS standard, the name and comment are generated according to a special algorithm, using data loaded from XML files.

Group D from OBIS identifier is used as the first hierarchy level - data processing method (current, accumulated value, maximum, minimum, etc.). However, the consistency between the numeric identifier and the text is prescribed in Types.xml file.

The second and the third level is formed based on the group C identifier (OBIS identifier) - parameter type. However, the consistency between the numeric identifier and the text is prescribed in Parameters.xml. The "Pararameter Name" parameter defines the name of the second level, while the "Name" parameter defines the name of the third level.

If group D identifier (tariff number or harmonic number) has a number other than 0, then the number of this tariff or harmonic is added to the end of the variable name.

Parameters of Profile Generic objects are loaded from Archives.xml file. The matching of the group C (for archives the group ID is 98 or 99), group D and group E are checked. The power profile name and its description are displayer based on the found parameters.

The part of OBIS codes of DLMS standard are reserved for national standard parameters as well as certain manufacturers. Those are codes of group C - 94 (national standard) and codes - 128..199 (codes for manufacturers). If the utility detects such a code, then the full name and description are loaded from the ExtendedCodes.csv file

Note. All the listed XML and CSV files can be edited by user (before the utility startup). Thus you can adapt the naming of the values and comments at the stage of data loading from the device and you can also extend the list of nonstandard codes in ExtendedCodes.csv file. In this case, it is recommended to save the changed files in order to avoid overwriting them when reinstalling the OPC server. The files are located in the folder С:\ProgramData\InSAT\Multi-Protocol MasterOPC Server\serverimport\dlms\

If OBIS code is not identified (its definition is not found in XML and CSV files), it is added to a separate group UNKNOWN_ITEMS.